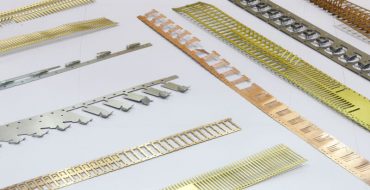

DEEP DRAWN STAMPING PARTS

From small parts to large parts, Kway Engineering has the personnel, equipment and experience to provide quality deep draw stamping and deep draw forming of parts to your given specifications. Our engineering and tooling staff has provided multiple deep drawing solutions for a variety of industries.

And we can do it in a variety of materials, including stainless, cold rolled carbon, low alloy, and commercial and high-strength carbon steels, as well as aluminum, copper, brass, and more.

Bring your custom application to Kway Engineering and we’ll show you what we can do to improve your metal stamping forming projects.

About Deep Drawing

Deep drawing is one of the most popular metal forming methods available to manufacturers–it involves the use of metal dies to form blank sheets of metal into a desired shape. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing.

The deep draw forming process begins with metal blanks. Typically, single blanks are used in order to facilitate the creation of parts or products with deeper shapes. Sometimes, these metal blanks will be placed on a reel to enable the metal to form efficiently. At each step in the deep drawing process, the metal blank is shaped through pressure applied by a metal die.

Though deep drawing is similar to metal stamping, the terms are not interchangeable. Stamping does not leave a single machine until the metal has completely formed. In general, deep drawing is used to fabricate parts and products that are deeper than metal stamping can accommodate.

Previous

Next